-

JALTEST TRAILER KIT (HARDWARE + SOFTWARE)

Precio habitual $1,472.19 USDPrecio habitual -

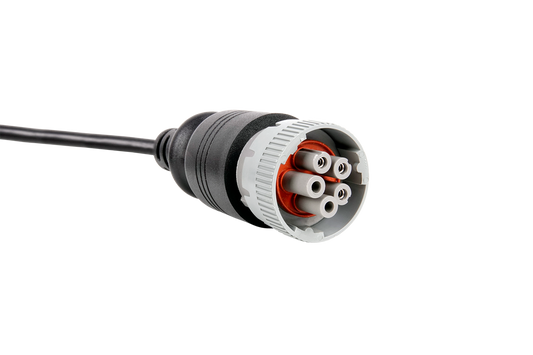

Carrier CAN diagnostics cable (Trailer)

Precio habitual $76.68 USDPrecio habitual -

Carrier diagnostics cable (Trailer)

Precio habitual $110.76 USDPrecio habitual -

Thermoking diagnostics cable (Trailer)

Precio habitual $127.80 USDPrecio habitual -

Deutsch 9 pin, PLC adapter (Trailer)

Precio habitual $306.72 USDPrecio habitual -

Haldex EB+ diagnostics cable (Trailer)

Precio habitual $59.64 USDPrecio habitual -

JALTEST TRAILER LICENSE RENEWAL

Precio habitual $276.90 USDPrecio habitual

Colección: Jaltest Trailer Diagnostics

Jaltest Trailer Diagnostics — EBS, ABS, Refrigeration & More

Trailers are not dumb boxes anymore. A modern refrigerated trailer has more electronic control modules than a truck from 15 years ago. Electronic braking systems, air suspension controllers, refrigeration unit computers, tire pressure monitoring systems, LED lighting modules, and telematics units all communicate on data networks that require dedicated diagnostic access. Jaltest trailer diagnostics give you full OEM-level control over every electronic system bolted to the trailer — from the Knorr-Bremse TEBS module managing the brakes to the ThermoKing controller keeping produce at 34 degrees.

If your shop inspects, repairs, or services trailers — whether you are a dedicated trailer service facility, a fleet maintenance operation, a reefer shop, or a general truck repair shop that touches trailers — this is the diagnostic platform that replaces the half-dozen brand-specific tools you have been accumulating.

Supported Trailer System Manufacturers

Unlike trucks and buses where coverage is organized by vehicle manufacturer, trailer diagnostics are organized by component manufacturer. The trailer OEM (Great Dane, Wabash, Utility, Hyundai Translead, Vanguard, Stoughton) builds the box, but the electronic systems inside come from a handful of specialized suppliers. Jaltest covers all of them:

| Manufacturer | Systems Covered | Key Capabilities |

|---|---|---|

| BENDIX | Trailer ABS | Fault code reading/clearing, wheel speed sensor diagnostics, modulator valve testing, ABS lamp verification, configuration programming |

| CARRIER | Refrigeration units | Full Carrier Transicold diagnostics — Vector, Supra, X-Series units. Engine/compressor data, setpoint programming, alarm history, defrost cycling, pre-trip test initiation, fuel system diagnostics |

| COJALI | Trailer electronics | Cojali-manufactured trailer EBS and lighting modules — native Jaltest support with full diagnostics and configuration |

| HALDEX | EBS, ABS, ECAS | Full Haldex EB+ electronic braking system diagnostics, ABS fault management, ECAS (Electronically Controlled Air Suspension) ride height calibration and diagnostics |

| KNORR-BREMSE | EBS, ABS, TEBS | Knorr-Bremse TEBS (Trailer Electronic Braking System) — full module diagnostics, brake performance monitoring, RSS (Roll Stability Support), TPMS integration, parameter programming, and brake system configuration |

| THERMOKING | Refrigeration units | Full ThermoKing diagnostics — SLXi, SLXe, Precedent, UT Series, T-Series units. Engine data, compressor status, temperature monitoring, alarm codes, defrost management, pre-trip diagnostics, hour meter readings |

| WABASH | Trailer ABS | Wabash National trailer ABS system diagnostics and configuration |

| WABCO | EBS, ABS, ECAS | WABCO Trailer EBS — full diagnostic access, ABS module testing, ECAS air suspension control, OptiTire TPMS integration, SmartBoard trailer monitoring, and brake wear indicators |

Trailer Types Covered

Jaltest trailer diagnostics apply to every type of trailer on the road. The electronic systems vary by trailer type, but the diagnostic platform covers all of them:

Dry Van Trailers

The most common trailer on the road. Modern dry vans from Great Dane, Wabash, Utility, and Hyundai Translead are equipped with electronic ABS or EBS, LED lighting modules with CAN-bus communication, tire pressure monitoring, and often telematics systems for load tracking. Jaltest covers the braking system diagnostics (Bendix, Wabco, Haldex, Knorr-Bremse), lighting module configuration, and TPMS sensors that keep these trailers DOT-compliant and rolling.

Refrigerated Trailers (Reefers)

Reefer trailers are the most electronically complex trailers on the road, and they demand the most diagnostic attention. The refrigeration unit alone — whether Carrier Transicold or ThermoKing — contains an engine, compressor, evaporator, condenser, and a computer that manages the entire thermal cycle. Add the trailer own EBS/ABS, air suspension, and TPMS systems, and you have a rolling network of electronic modules that all need periodic service.

Jaltest provides full diagnostic access to both major refrigeration unit manufacturers:

- Carrier Transicold — Vector 8500/8600, Supra 850/1050/1150, X2/X4 Series. Read and clear alarm codes, monitor compressor discharge and suction pressures, view engine data (RPM, coolant temp, oil pressure), program temperature setpoints and multi-temperature zone configurations, run pre-trip test sequences, access defrost cycle controls, and read fuel consumption data.

- ThermoKing — SLXi 200/300/400, SLXe 200/300/400, Precedent S600/S700, T-Series (truck units), UT Series. Full alarm history and active alarm diagnostics, temperature sensor readings (supply air, return air, box temp), compressor and engine monitoring, defrost management, hour meter and maintenance interval tracking, and pre-trip verification.

For reefer shops and food/pharmaceutical carriers, the ability to diagnose refrigeration units in-house — instead of calling a Carrier or ThermoKing dealer — means faster turnaround, lower service costs, and tighter control over your cold chain. When a reefer alarm goes off at 2 AM and your load of temperature-sensitive pharmaceuticals is at risk, waiting for a dealer to open at 8 AM is not an option.

Flatbed Trailers

Flatbeds, step decks, and lowboys may be simpler than reefers, but modern flatbed trailers still run electronic ABS (required by FMCSA since 1998 for new trailers), often have air-ride suspension with electronic controls, and increasingly include TPMS and LED lighting modules. Jaltest covers the ABS and suspension electronics on these platforms.

Tanker Trailers

Fuel tankers, chemical haulers, dry bulk pneumatic trailers, and food-grade liquid tankers all share the same electronic braking, suspension, and lighting systems as other trailer types. Tanker trailers also frequently include roll stability systems (RSS) that work in conjunction with the EBS to prevent rollovers — a critical safety function that Jaltest can diagnose and verify. Some tanker trailers also have electronic vapor recovery and level monitoring systems.

Curtainsiders and Specialty Trailers

Curtainside (tautliner) trailers, container chassis, intermodal platforms, and specialty-purpose trailers all use standard trailer EBS/ABS, suspension, and lighting systems that Jaltest covers. If it has electronic brakes and plugs into a tractor, Jaltest can diagnose it.

Diagnostic Capabilities — What You Can Do

Electronic Braking System (EBS) Diagnostics

EBS is the backbone of modern trailer safety. It replaces the traditional relay valve with electronic control of each brake on the trailer, providing faster response times, integrated roll stability, and brake wear monitoring. Jaltest gives you full access:

- Read and clear EBS fault codes across all supported manufacturers (Knorr-Bremse, Wabco, Haldex)

- Monitor wheel speed sensors in real time — identify intermittent signal dropouts that cause ABS faults

- Test EBS modulator valves — verify each brake circuit is responding correctly

- View brake performance data — application pressure, response time, brake force distribution

- Roll Stability Support (RSS) diagnostics — verify accelerometer calibration, lateral force thresholds, and intervention history

- Program EBS parameters — trailer configuration (axle count, brake type, load sensing), braking force distribution, compatibility mode settings

- Reset brake pad wear indicators after brake service

ABS Diagnostics

Older trailers and certain configurations still use ABS-only systems (no EBS). Jaltest covers Bendix, Wabco, Haldex, and Knorr-Bremse trailer ABS modules with:

- Fault code reading and clearing

- Wheel speed sensor testing — signal amplitude, air gap verification, tone ring condition

- Modulator valve activation — command individual valves to verify function

- ABS warning lamp verification — confirm the lamp illuminates and extinguishes correctly during the self-test cycle

- Configuration programming — number of axles, sensor type, modulator type

ECAS (Air Suspension) Diagnostics

Electronically Controlled Air Suspension manages ride height, load leveling, and dock height adjustment on air-ride trailers. Jaltest covers ECAS systems from Wabco and Haldex with:

- Ride height sensor calibration — set nominal ride height after replacing sensors or air bags

- Load leveling system diagnostics — verify left/right balance, monitor air spring pressures

- Raise/lower commands — actuate the suspension from the diagnostic interface for testing

- Fault code management — solenoid valve faults, height sensor faults, overload warnings

- Parameter programming — ride height settings, raise/lower speed, overload thresholds

Tire Pressure Monitoring (TPMS)

Trailer TPMS systems from Wabco (OptiTire), Continental, and other suppliers monitor individual tire pressures and temperatures in real time, alerting the driver to underinflation or overheating conditions that lead to blowouts. Jaltest accesses the TPMS module to:

- Read sensor data — individual tire pressures and temperatures for every position

- Register new sensors after tire service or sensor replacement

- Set pressure thresholds — configure low-pressure and high-temperature alarm points

- View alarm history — identify positions with recurring issues

Lighting Module Diagnostics

Modern trailers increasingly use CAN-bus controlled LED lighting systems that communicate digitally with the tractor. Jaltest can diagnose lighting module faults, verify circuit continuity, test individual lamp outputs, and configure lighting parameters.

Why Trailer Diagnostics Matter

Trailers are often the neglected half of the commercial vehicle equation. Shops invest in truck diagnostic tools but rely on a blinking ABS light and a test cord to diagnose trailer issues. Here is why that approach is costing you:

DOT Compliance

Federal Motor Carrier Safety Regulations require functioning ABS on all trailers manufactured after March 1, 1998. An ABS malfunction indicator lamp that stays on after the self-test cycle is a DOT violation. During a roadside inspection, a non-functioning trailer ABS system can result in the trailer being placed out of service. Jaltest lets you verify ABS function, clear false fault codes, and document compliance before the trailer leaves your lot.

Brake Safety

Electronic braking systems with roll stability are the most significant safety technology on a modern trailer. When the EBS is not functioning correctly, brake response times increase, roll stability intervention does not activate, and brake force distribution defaults to a less-than-optimal mechanical backup. Diagnosing and correcting EBS faults is not optional — it is a safety imperative.

Reefer Temperature Chain Integrity

For food carriers, pharmaceutical distributors, and any company hauling temperature-sensitive freight, a reefer unit failure is a financial catastrophe. A truckload of pharmaceutical product can be worth $500,000 or more. A full load of fresh produce runs $50,000-100,000. When the reefer alarms, you need diagnostics immediately — not in three days when the Carrier dealer can fit you in. Jaltest puts reefer diagnostic capability in your own shop, on your own schedule.

Preventive Maintenance

Trailer EBS and ABS systems store historical data that reveals developing problems before they become failures. Brake wear indicators can tell you which trailers are due for brake service before the next inspection. TPMS data can identify tire positions with slow leaks. Reefer hour meters and maintenance interval counters can trigger scheduled service. Jaltest turns your trailer fleet maintenance from reactive to proactive.

Trailer Diagnostic Connectivity

Trailer diagnostics use a different connector and protocol than trucks. The standard trailer diagnostic connection is through the 7-pin or 15-pin trailer connector using the ISO 11992 protocol for EBS/ABS communication between the tractor and trailer. For standalone trailer diagnostics (connecting directly to the trailer without a tractor), Jaltest connects through the trailer diagnostic socket — typically a 7-pin ISO 7638 connector on the trailer frame near the ABS module.

Refrigeration units (Carrier and ThermoKing) use their own diagnostic connectors, usually located on or near the reefer control panel. Jaltest includes the appropriate adapter cables for both Carrier and ThermoKing diagnostic ports. This means your technician can diagnose the trailer braking system AND the reefer unit from the same Jaltest interface using the same laptop — no switching between separate Carrier DataLink and ThermoKing OptiSet tools.

For shops that service both trucks and trailers, the Jaltest cable kit includes adapters for both vehicle types. You do not need to purchase separate cable sets for truck versus trailer work.

Trailer Telematics Integration

Modern trailer fleets increasingly deploy telematics systems — Wabco SmartBoard, Knorr-Bremse iTAP, and third-party units from SkyBitz, Spireon, and CalAmp — that report trailer location, load status, reefer temperature, brake condition, and tire pressure to fleet management platforms. When the telematics system reports an issue, your technician needs a diagnostic tool that can verify the condition, read the specific fault codes, and determine the corrective action.

Jaltest complements trailer telematics by providing the deep diagnostic access that telematics alerts point to but cannot resolve. When SmartBoard reports an EBS fault on trailer 4721, Jaltest reads the specific fault code, identifies the affected component, and guides the technician through the repair — from diagnosis to verification that the fault has been corrected.

Who Needs Jaltest Trailer Diagnostics

- Dedicated trailer service facilities — if trailers are your primary business, Jaltest is the comprehensive diagnostic platform that covers every EBS, ABS, refrigeration, and suspension system you will encounter

- Reefer repair shops — full Carrier Transicold and ThermoKing diagnostics without OEM dealer dependence

- Fleet maintenance operations — diagnose trailer issues in-house instead of sending trailers to a specialty shop or dealer

- Truck repair shops expanding into trailer work — adding Jaltest trailer capability to an existing truck diagnostic setup is a revenue-expanding move. Many shops do truck work but turn away trailer diagnostic jobs because they lack the tooling

- DOT inspection stations — verify ABS and EBS function with actual diagnostic data, not just a lamp check

- Leasing companies — trailer leasing operations (TIP, GATX, Milestone) need to maintain large fleets of diverse-age trailers with various EBS/ABS configurations

Licensing

Jaltest offers a dedicated Modular Trailer License that covers all trailer component manufacturers (Bendix, Carrier, Haldex, Knorr-Bremse, ThermoKing, Wabco) in a single subscription. This can be purchased standalone or bundled with a truck license for shops that service both power units and trailers.

The trailer license is also included in the Full Commercial Vehicle License, which covers trucks, buses, trailers, and light commercial vehicles.

Free Shipping, Full Warranty, Live Support

Every Jaltest trailer diagnostic kit from Diesel Truck Diagnostic Tools ships free with full manufacturer warranty and our 30-day satisfaction guarantee. When your technician is trying to figure out why a Knorr-Bremse TEBS module is throwing a wheel speed sensor fault on axle 3, our trained staff at 866-217-0063 can walk through the diagnostics step by step.

We have been configuring Jaltest kits for trailer service operations since 2016. We know which cables you need for trailer diagnostics (hint: it is different from the truck cable set), and we will make sure your kit arrives ready to connect.

Get Started

Browse the trailer diagnostic kits below, or explore related categories: Truck Diagnostics, Bus Diagnostics, Light Commercial Vehicle Diagnostics, or the full Commercial Vehicle Diagnostics overview.

Questions about which kit covers your trailer service needs? Call 866-217-0063 or email support@dieseltruckdiagnostictools.com. We will help you match the right Jaltest configuration to your trailer fleet and workload.